ASA COLOR LENS

【Visible light, UV, IR】

Collaborating with a material maker to develop transparent silicone, ASAHI RUBBER was the first to commercialize the new material as lens for all sectors such as general lighting, ultra-violet irradiator, automotive.

We keep providing lens solutions to our customers, supporting in all aspects of material/structure/optical performance backed by its ample experience.

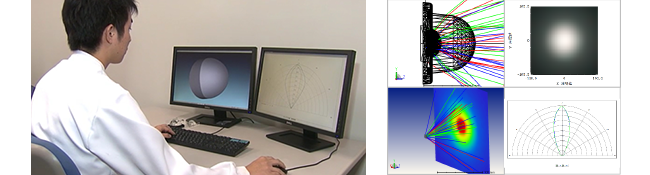

Optical design: Design service, with or without materialization, is available. Lots of experience especially on lighting lens.

Materials: Best material selections from all major silicone makers.

Siloxane: Our special treatment can remove siloxane to the utmost limit. Feel free to contact us if you are looking for solutions in lighting lens.

What are transparent resins with excellent characteristics and expanding applications?

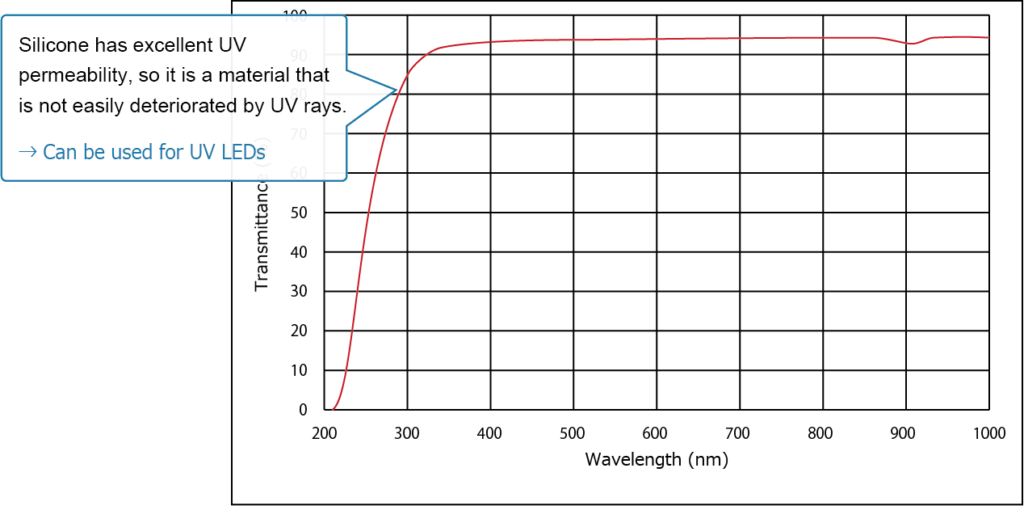

Best for NUV LEDs or blue LEDs, since ASA COLOR lens works well at a wavelength of 365nm.

ASA COLOR lens is transparent over NUV~NIR(350~1,000nm), with an excellent overall transmittance of 95.4%.※THK:2mm. Just for reference, none guaranteed value.

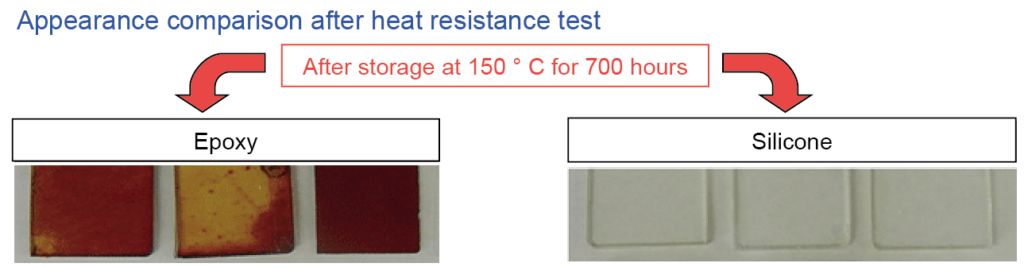

Passed an oven test of 150 ℃×1,000h Reflow solder tolerant (275℃)

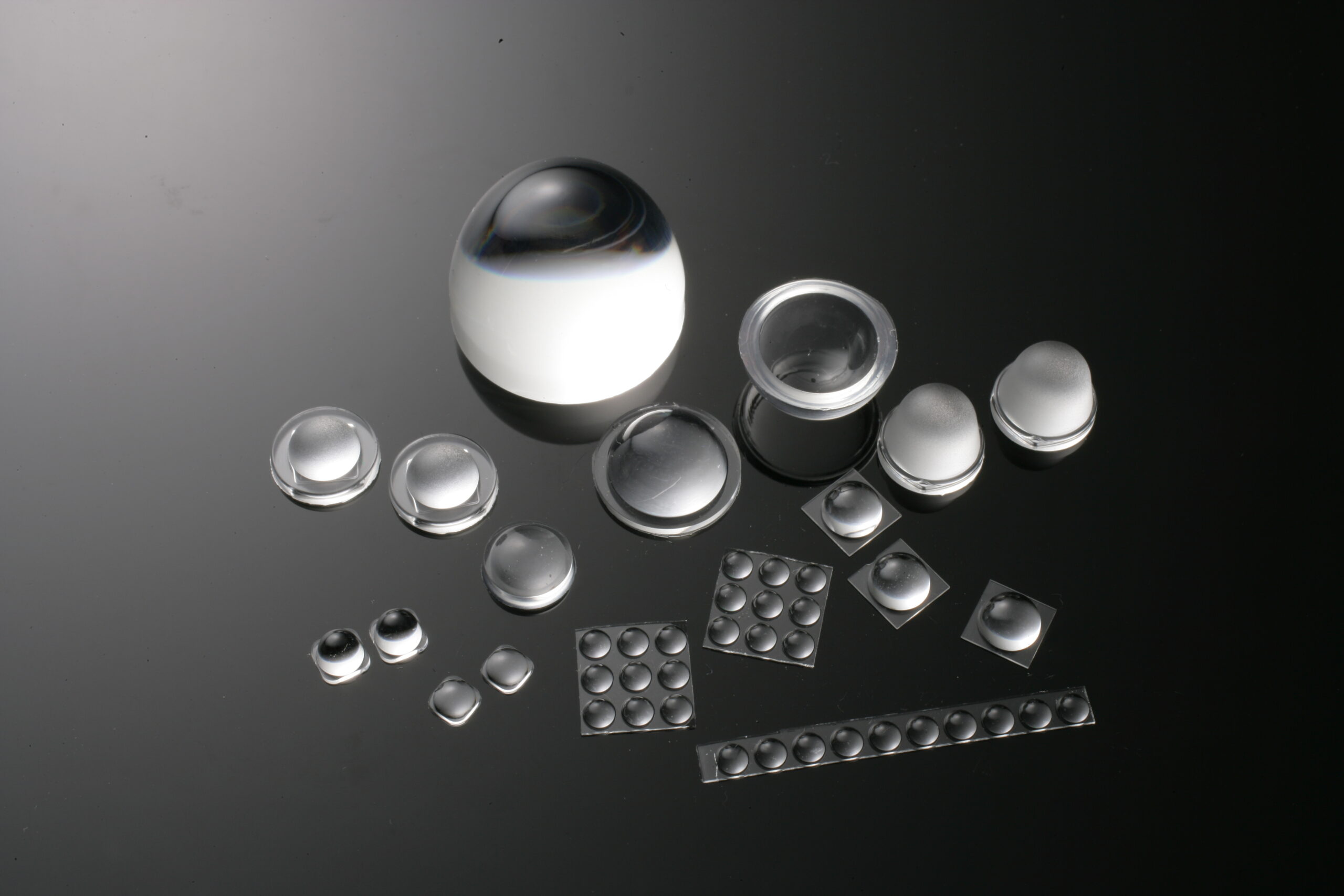

Independent on product size, our accumulated molding technology brings complex shape products.

Advise me on the price.

Advise me on the fixation methods.

Can you offer microfabrication and/or complex shape?

What is the largest size you can mold?

We offer design for not only lens optics but also for fixation devices. Feel free to contact us.

〈Contribution in the market〉

Automotive lighting component / General lighting / Signage / lens for LED devices / Ultra-violet irradiator / Infrared transmitter receiver / Medical applications

Aspheric lens / Convex lens / Fly-eye lens / Fresnel lens / Cylindrical lens / Free form lens / Rod lens / Light pipe

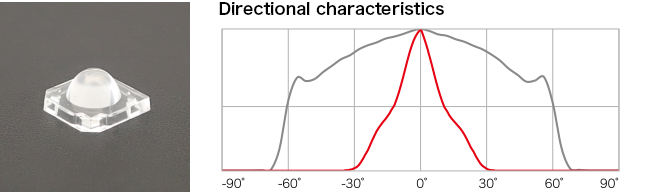

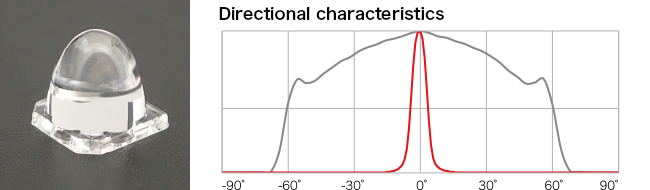

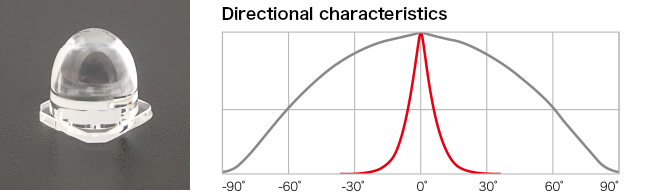

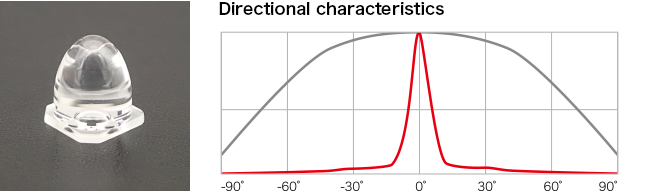

AL-30M-033K3

Outline: 9.5 x 9.5 mm/height: 4.8 mm

Supported LED:NCSU 033 C, NCSU 033 B, NCSU 034 B

Direction angle : 30°

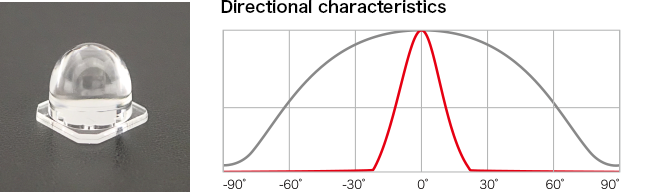

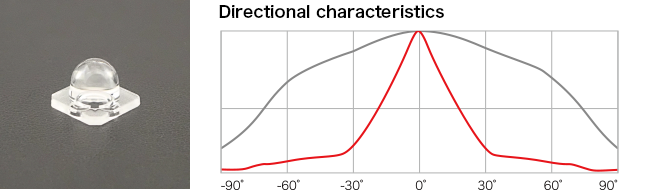

AL-8M-033

Outline: 12.0 × 12.0 mm/height: 11.1 mm

Supported LED:NCSU 033 C, NCSU 033 B, NCSU 034 B

Direction angle: 8°

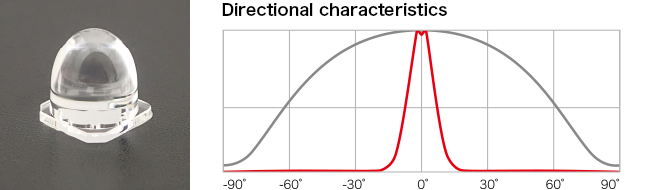

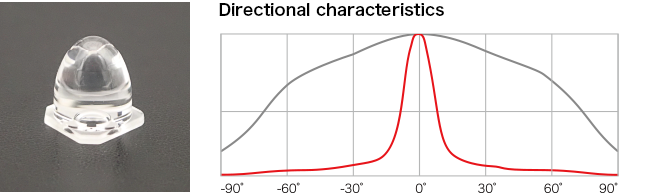

AL-22M-233

Outline: 10.0 × 10.0 mm/height: 9.0mm

Supported LED:NVSU 233 B, NVSU 233 A

Direction angle : 23°

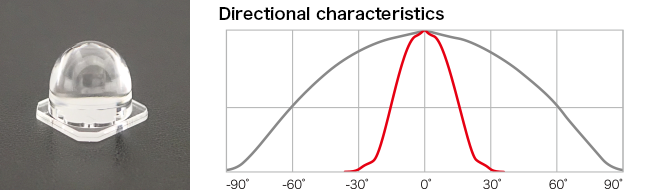

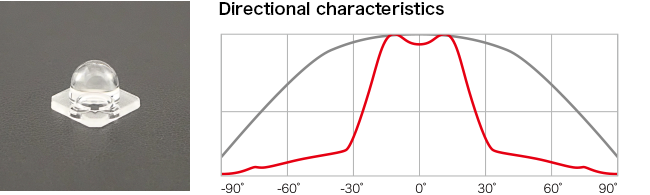

AL-12M-233

Outline: 10.0 × 10.0 mm/height: 10.5 mm

Supported LED:NVSU 233 B, NVSU 233 A

Direction angle : 12°

AL-30M-275

Outline: 10.0 × 10.0 mm/height: 9.0mm

Supported LED:NCSU275

Direction angle : 30°

*This is the same product as AL-22M-233 product.

AL-10M-275

Outline: 10.0 × 10.0 mm/height: 10.5 mm

Supported LED:NCSU275

Direction angle: 10°

*This is the same product as AL-12M-233 product.

AL-35M-119B

Outline: 8.0 x 8.0 mm/height: 5.8 mm

Supported LED:NVSU 119 C

Direction angle : 32°

AL-12M-119B

Outline: 9.0×9.0 mm/height: 10.5 mm

Supported LED:NVSU 119 C

Direction angle : 16°

AL-50M-276

Outline: 8.0 x 8.0 mm/height: 5.8 mm

Supported LED:NCSU 276 A

Direction angle: 50°

This is the same product as AL-35M-119B product.

AL-8M-276

Outline: 9.0×9.0 mm/height: 10.5 mm

Supported LED:NCSU 276 A

Direction angle: 8°

This is the same product as AL-12M-119B product.

| Color | Colorless transparency |

| Hardness | Degree of JIS A 80 |

| Refractive index (25℃) | 1.41 |

| Water absorption rate (23°C 24 hours pure water immersion) | 0.09% |

| Coefficient of linear expansion (40~200℃) | 27×10-5 |

Comparison with other materials used for lenses

| Transmittance at 365nm | Transmittance average 300~400nm | Refractive index Nd | Heat-resistant at 150℃ | |

|---|---|---|---|---|

| Silicone(Q) | 92% | 90.3% | 1.41 | ◎ |

| Cycloolefin polymer(COP) | 89% | 81.2% | 1.52 | × |

| Polymethyl methacrylate(PMMA) | 16% | 15.1% | 1.49 | × |

| Epoxy polymer(EP) | 0% | 4.5% | 1.56 | △ |

Silicone lenses withstand high temperatures and UV environments.